Design is the idea,

Glass the material

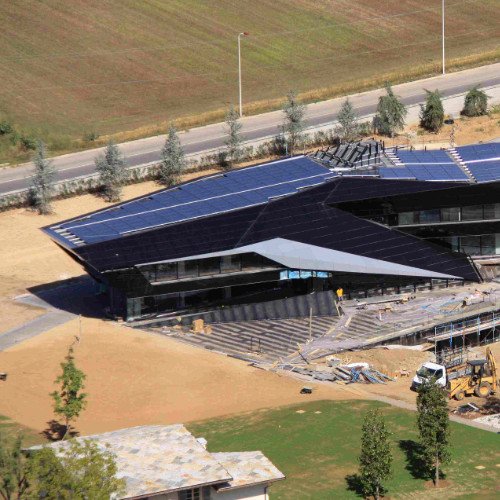

Quidam is the result of the evolution of forty years of flat

glass processing experience.

Building, architecture, interior design and furnishing

are our daily business.

A high level of technological expertise combined with constant updating translate into manufacturing innovation capable of meeting the ever-changing needs of architects, designers and companies.

TEMPERING AND HST LINE

Thermal tempering treatment imparts elevated mechanical and thermal resistance to the glass.Tempered glass is also a safety product, because in the event of breakage the glass tends to fracture into small and relatively harmless granules.The convection tempering line can process sheets also of very large dimensions and high thicknesses, in addition to the latest generation of Low-E magnetronic glass.

COATING LINE

The coating line allows us to produce tempered glass coated with ceramic inks that fuse

with the glass to provide extreme resistance to weathering, making the product ideal

also for building construction applications while also meeting stringent safety

prescriptions.

Sheets can be produced in colours to samples or in the RAL®, Pantone®, or NCS® colour ranges.

LAMINATION LINE

Laminated glass is composed of two or more sheets bonded together with plastic films.Laminated glass is a safety product because in the event of breakage the plastic film retains the fragments thereby protecting people and property in the vicinity.The lamination line allows the assembly of large size sheets with standard and coloured interlayers, and also with the innovative Saflex® DG and SentryGlas® structural plastic films.

DIRECT PRINTING LINE WITH CERAMIC INKS

Digital printing with ceramic inks allows us to reproduce graphic elements and decorations with screen-print quality levels.By means of the tempering process the glass sheet can be brought to the level of mechanical strength necessary for external applications, guaranteeing excellent resistance to weathering and colour changes.The very high opacity of the inks makes this technique suitable also printing enamel bands or frit borders.

AUTOMATED WAREHOUSE AND CUTTING LINE

The cutting line, which is fed from the automatic warehouse, can process large size float glass with thicknesses of up to 19mm.The advanced technological features of the plant include automatic labelling and removal of the temporary protective film (TPF) applied to protect the latest generation of Low-E glass.

STRAIGHT-BILATERAL-VERTICAL GRINDING AND DRILLING LINES

The four vertical and horizontal grinding lines allow all types of edge processing and finishing operations, in addition to the boring of cylindrical holes with countersinks and variable angle grinding.

MACHINING CENTRES

large size components, is carried out on numerically controlled machining centres. These plants also allow the creation of bevels, engravings and 3D machinings.

SCREEN PRINTINGS

Screen printing techniques are normally employed for partial obscuration of glass sheets.The inks are applied using screens that are compatible with series production operations.

SANDBLASTING

Sandblasting is an artisanal technique for glass surface treatment that can be employed to create delicate or deeper decorations, imparting a refined three dimensional effect to the sheets.

ADHESIVE BONDING

Glass-glass and glass-metal bonds of high mechanical strength and elevated transparency are created using UV curing techniques.

LOGISTICS

Collaboration with haulage companies specialised in handling large size glass sheets with the use of cranes and vacuum lifters, makes for optimised logistics and customer satisfaction.

Quidam's team of experts can provide invaluable technical support for every design need, addressed in full compliance with the legislation in force.

Strategia di Specializzazione Intelligente

Il progetto di innovazione di Quidam rientra nella Strategia di Specializzazione Intelligente regionale che si propone di sostenere gli investimenti produttivi connessi ai percorsi di consolidamento e diversificazione, al fine di conseguire un potenziamento della base produttiva regionale, il suo sviluppo tecnologico e la sua competività.

Azione 3.1.1 del POR FESR

Liguria 2014-2020

Azione 4.2.1 - Asse 4 Energia - del POR FESR Liguria

2014-2020

Azione 3.1.1 e 3.2.1 del POR FESR Liguria 2014-2020